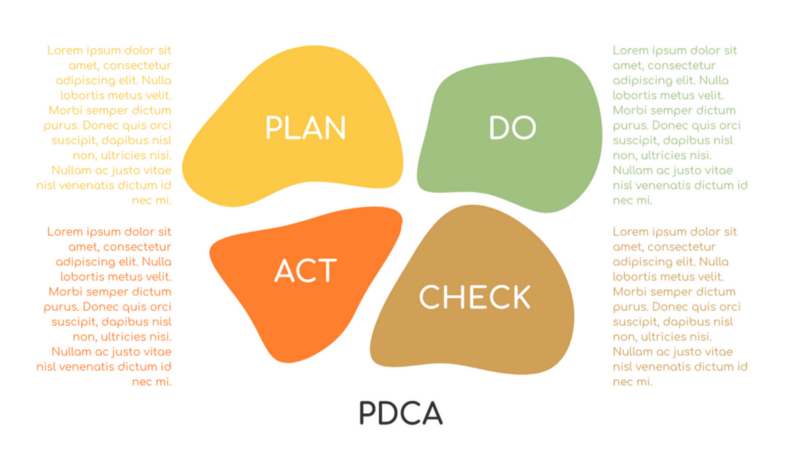

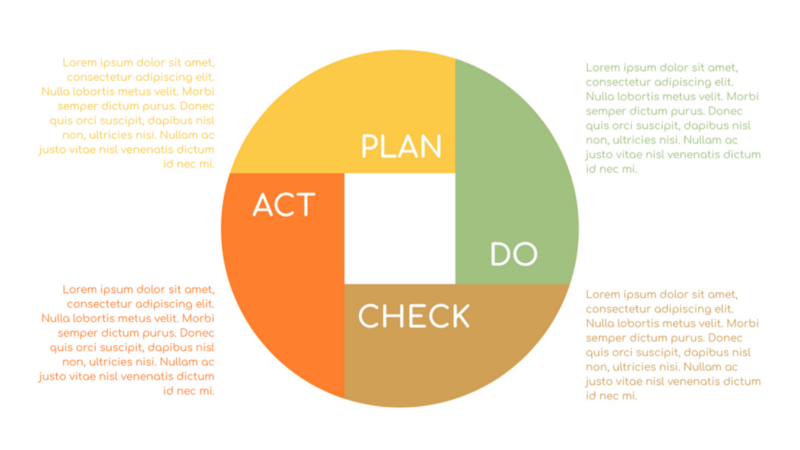

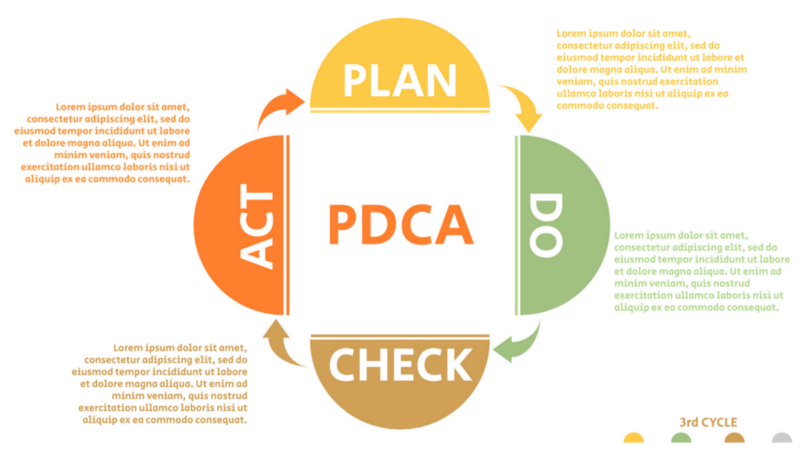

PDCA is considered one of the most popular frameworks for continuous improvement of business processes. PDCA (plan do check action), also known as Deming cycle, is the simplest framework for process improvement. Basically, it’s a series of feedback cycles of continuous improvement — you decide how it works, figure out how to improve it, eventually make changes, and keep repeating the cycle. I believe PDCA is the simplest and most effective way to help you improve your workflow.

PDCA cycle Widely Used in Many Fields

Deming believes that high quality does not come from product inspection based on results, but from continuous improvement based on process. Later, the concept was not only used in quality management, but also widely used in the field of enterprise management.

Toyota Approach

PDCA cycle has become one of the pillars of Toyota’s just-in-time production system. Over the past two decades, Toyota’s systems have become one of the most successful demonstrations of lean manufacturing using PDCA; For more information on Toyota’s use of PDCA in Lean Methods, see Jeffrey Lake’s The Toyota Method (2003).

According to Deming, you can apply PDCA for the following purposes:

- Having a system in place for continuous quality improvement

- Reducing defects through higher levels of quality uniformity

- Understanding what quality should mean within context

Continuous Improvement for Quality Management

In quality management, PDCA cycle is also widely used, and has achieved good results. Therefore, the PDCA cycle is called the basic method of quality management. For example, TQM is a scientific process that is developed and organized according to a quality plan. The process conforms to the PDCA cycle and runs continuously.

PCDA — An Integral Part of Six Sigma

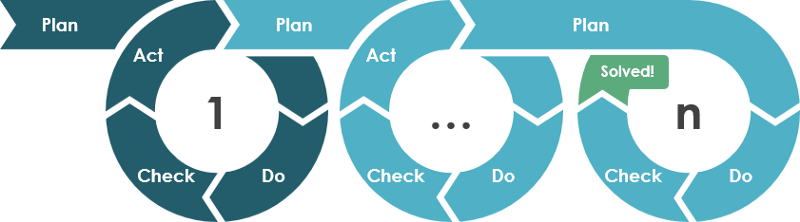

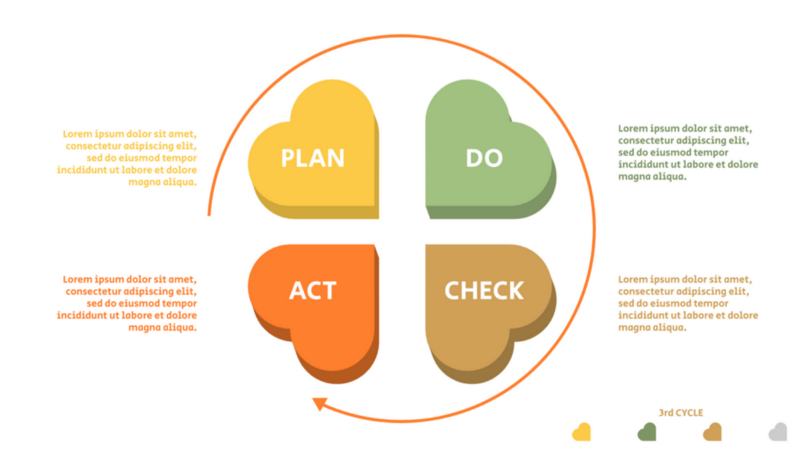

The PDCA cycle is a logical working procedure for doing any job efficiently. In Six Sigma quality management, PDCA cycle has been widely used and achieved good results, so some people say that PDCA cycle is the basic method of quality management. It is called the PDCA cycle because the four processes are not run once and finished, but over and over again. One cycle ends, some problems are solved, other problems may remain unresolved, or new problems may arise, and the next cycle begins.

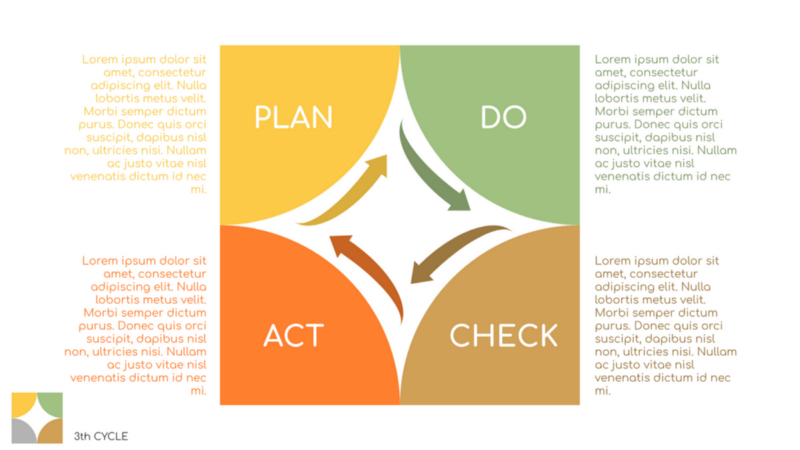

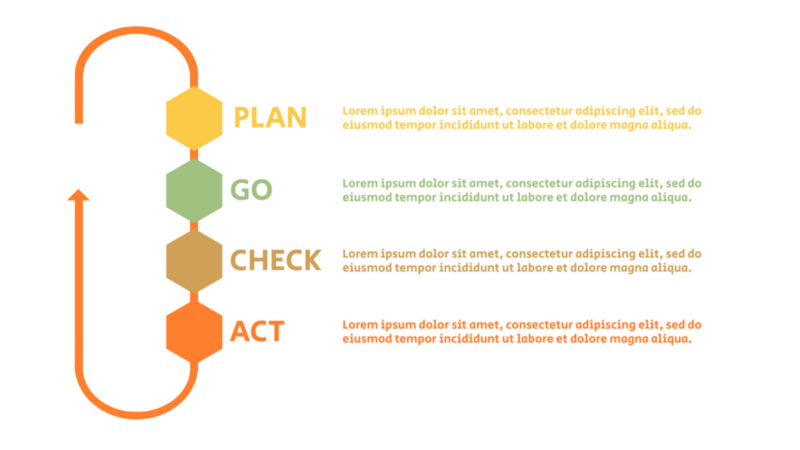

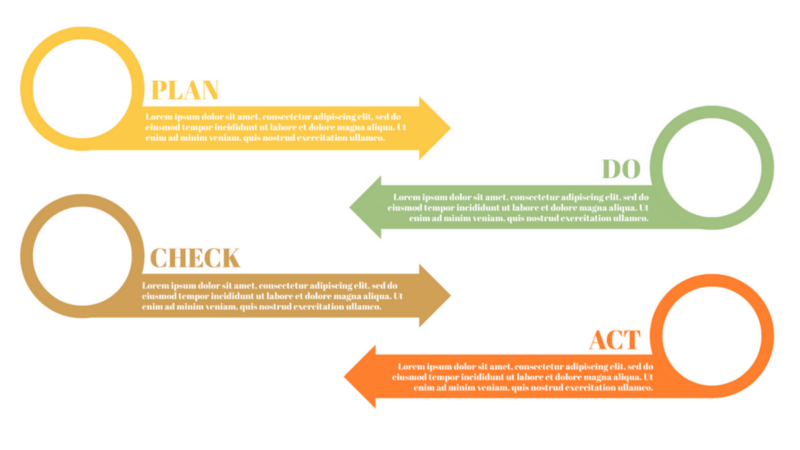

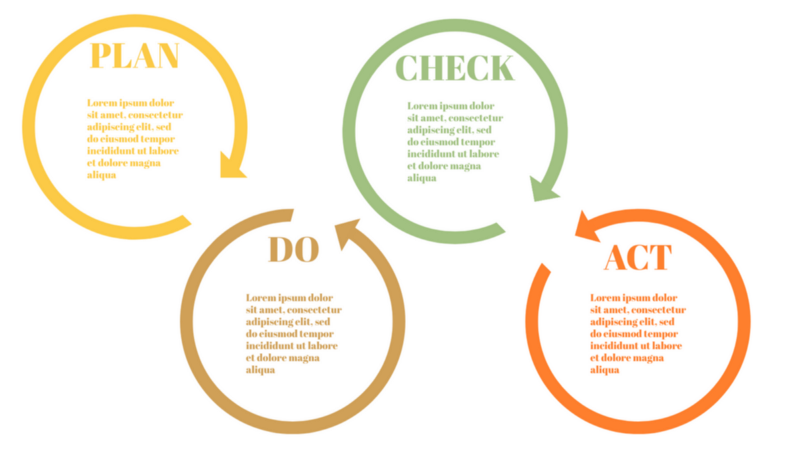

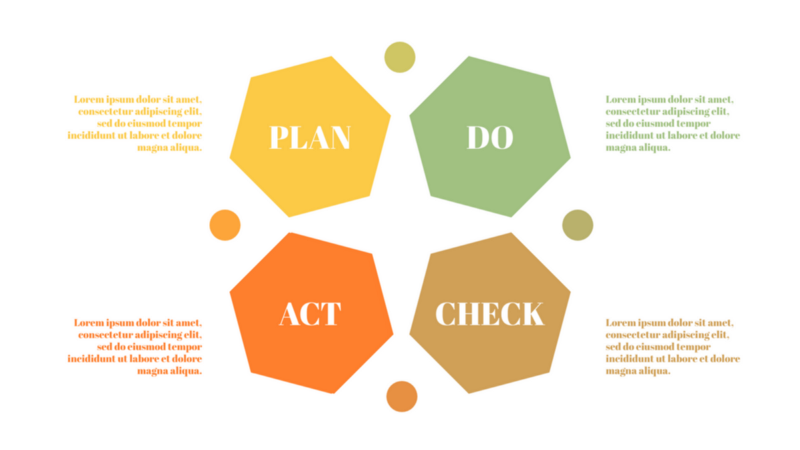

What Does the Deming Cycle Mean?

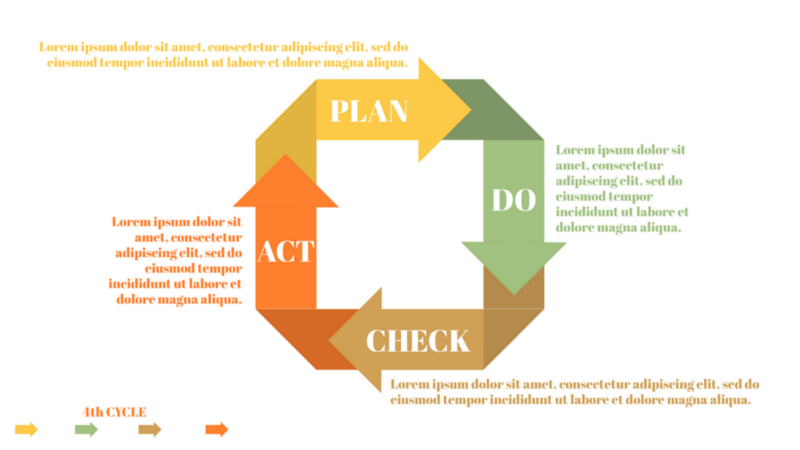

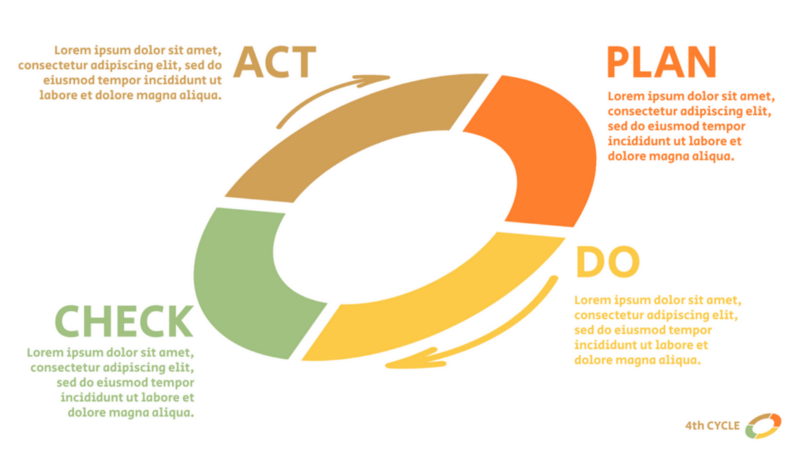

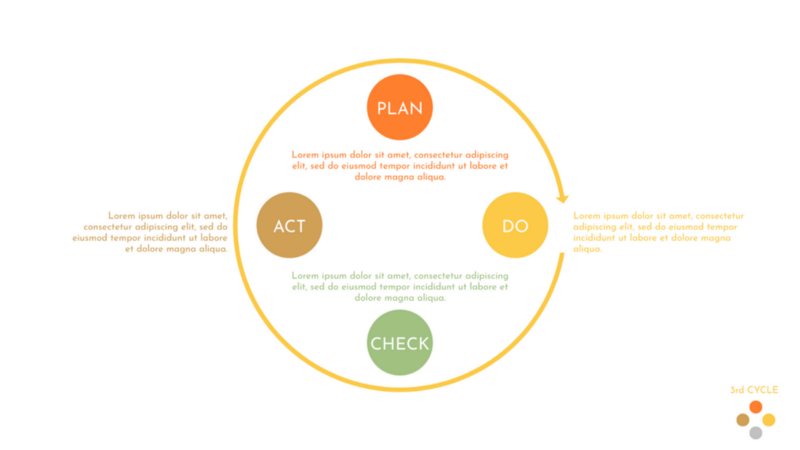

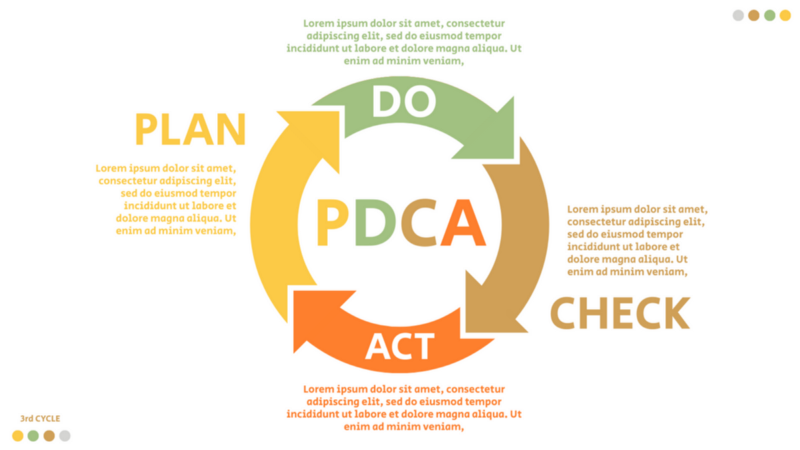

The Deming Cycle is a four-part management approach that advocates continuous improvement. This and other similar continuous improvement models have been integrated into business and enterprise or agile development.

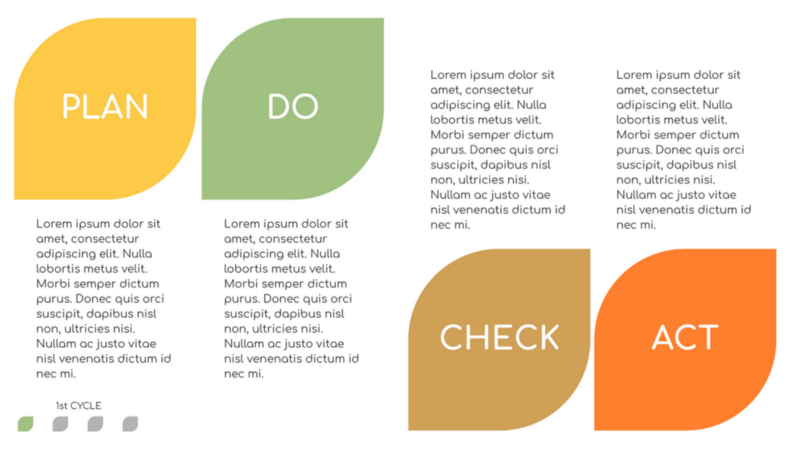

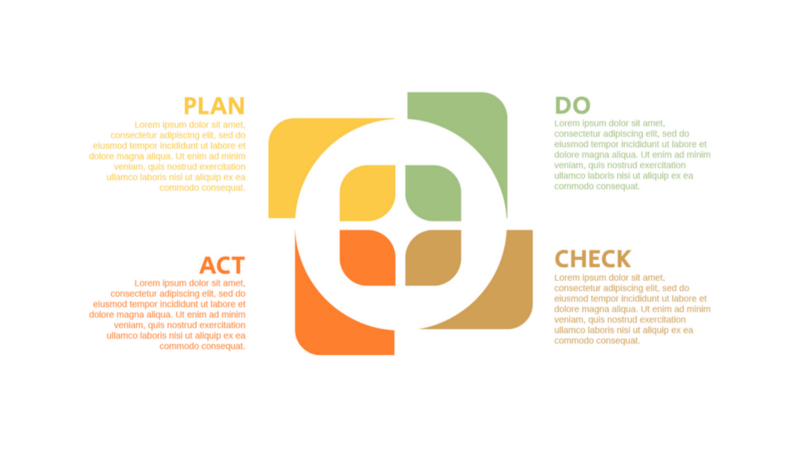

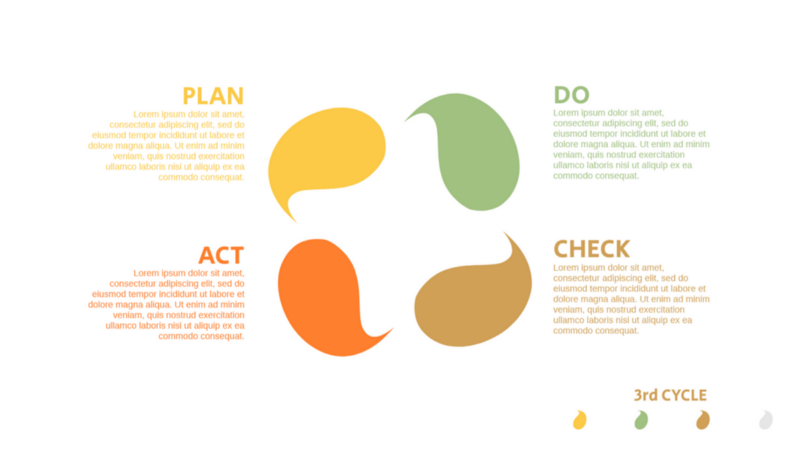

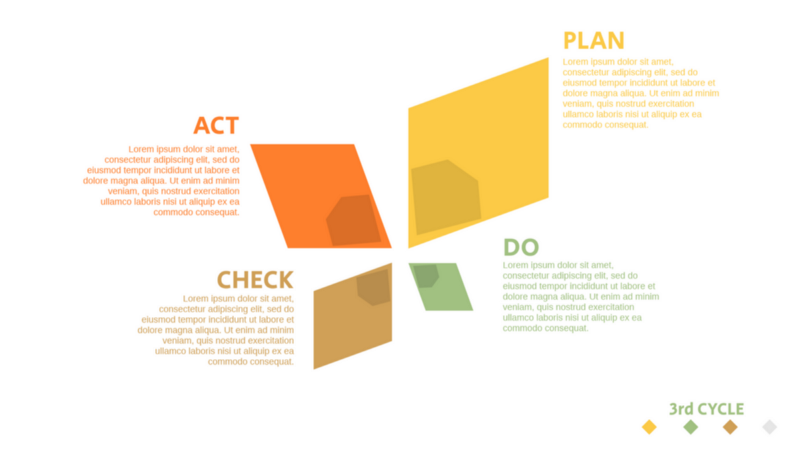

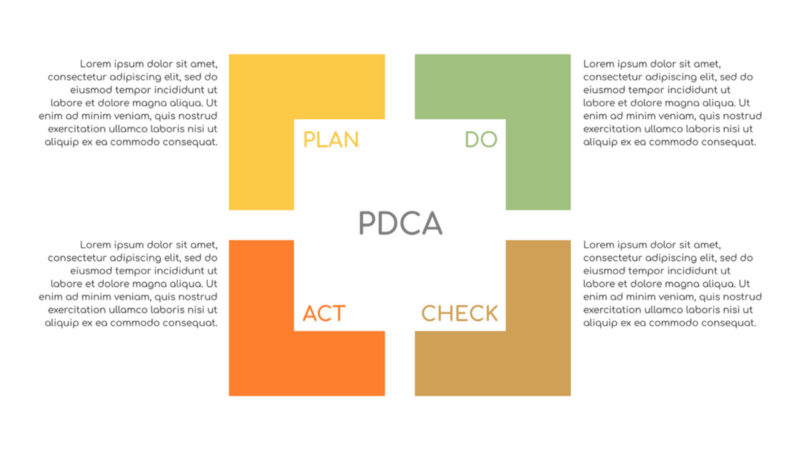

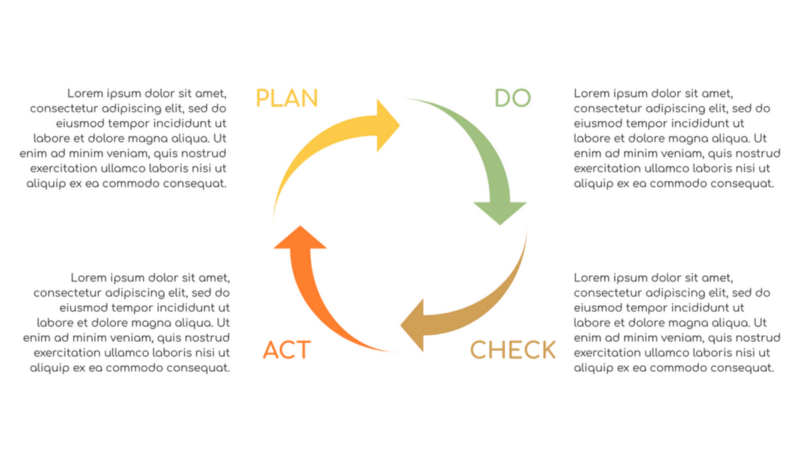

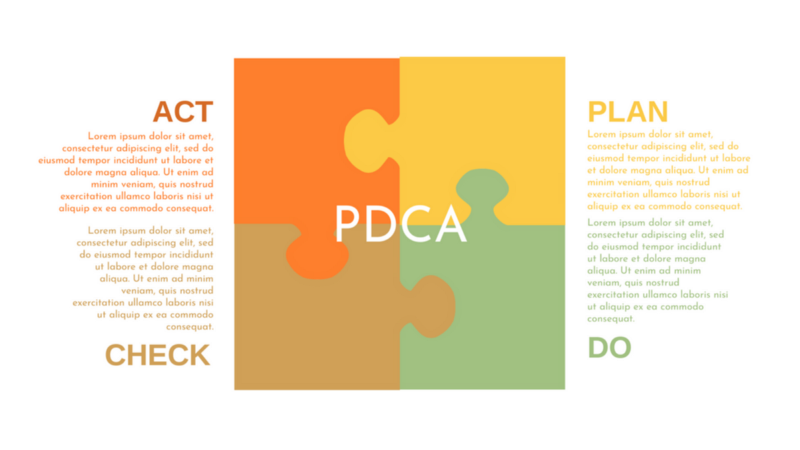

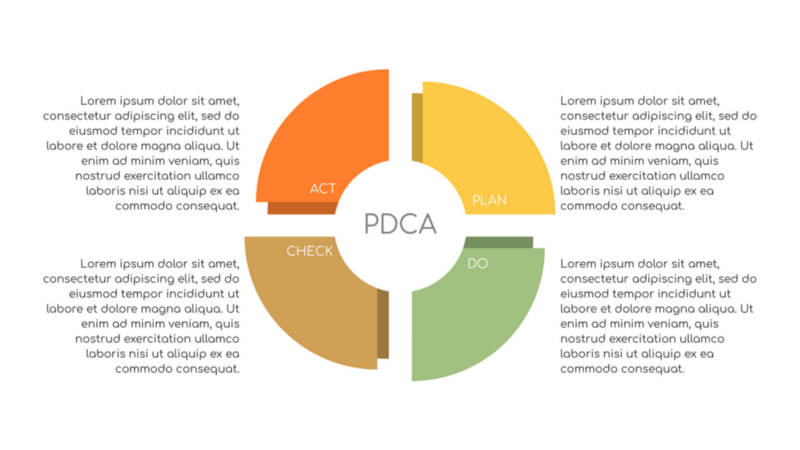

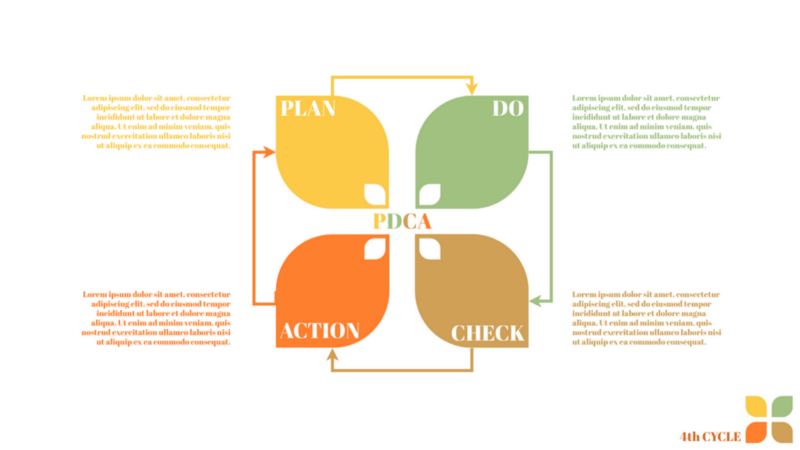

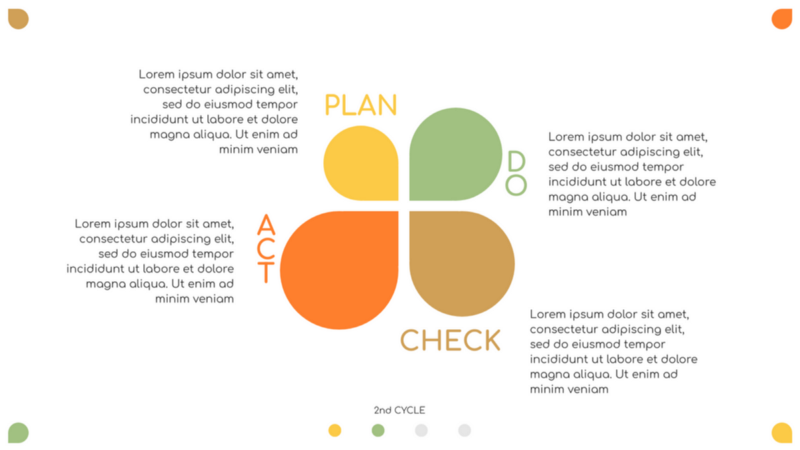

PDCA is the first letter of the English words “plan”, “do”, “check” and “act”. The PDCA cycle is an agile development process for quality management in a spiral mode, and the cycle continues. It is an iterative and incremental development process, not a one-time process.

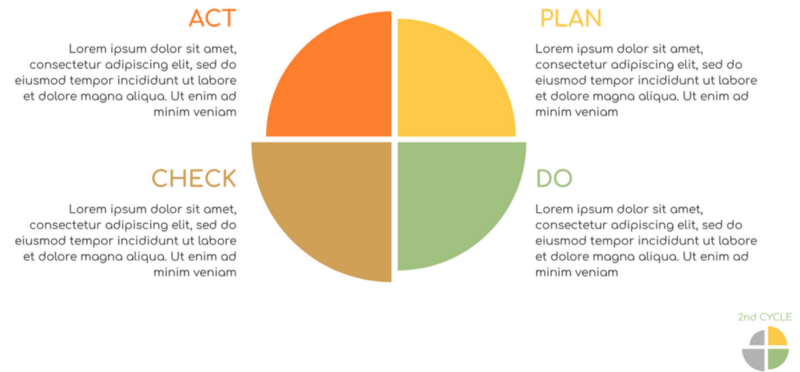

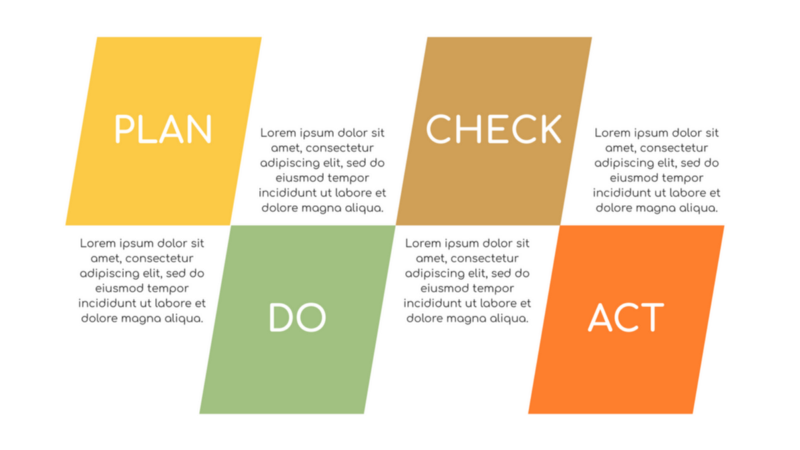

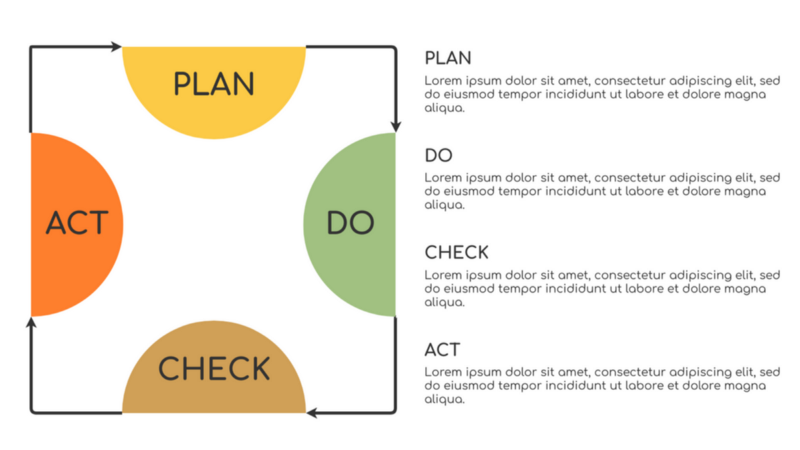

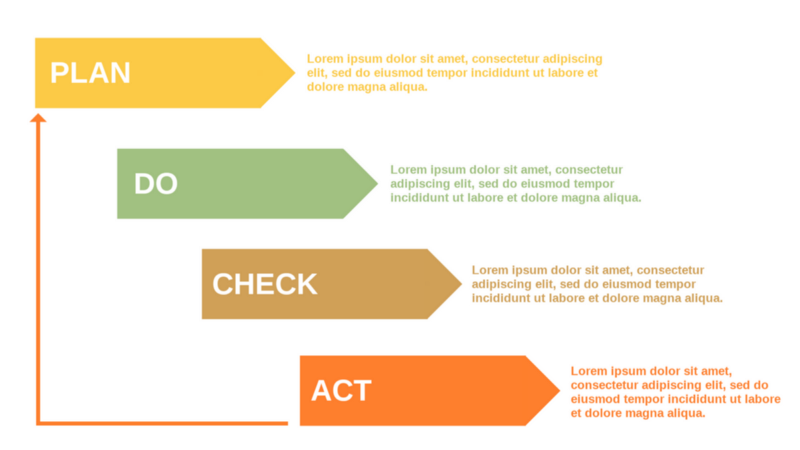

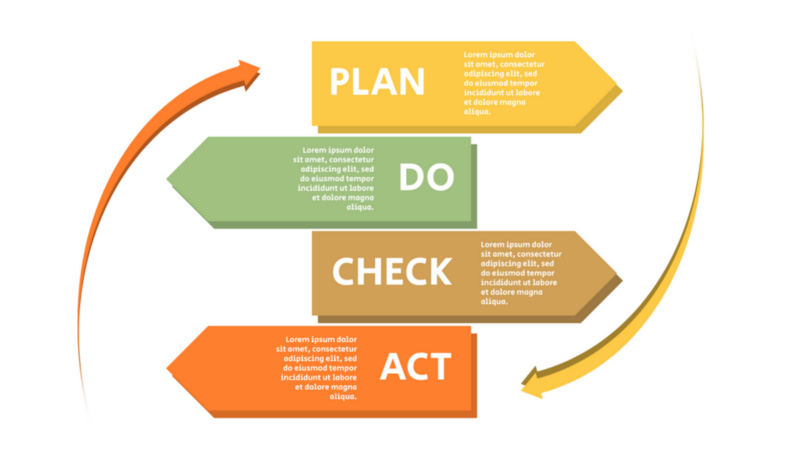

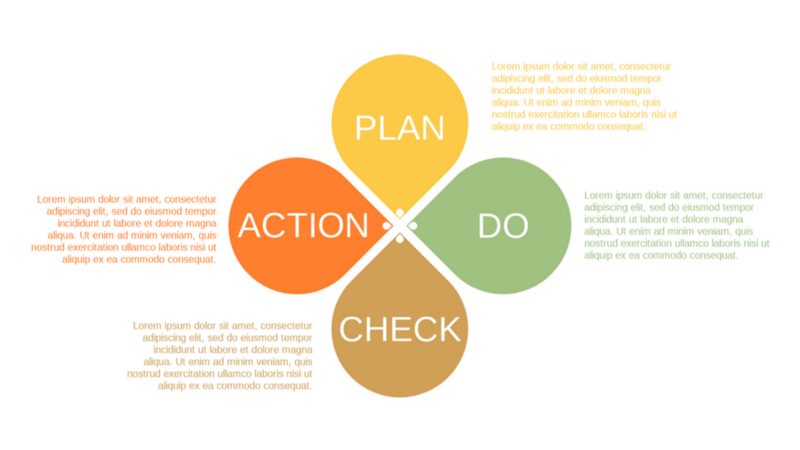

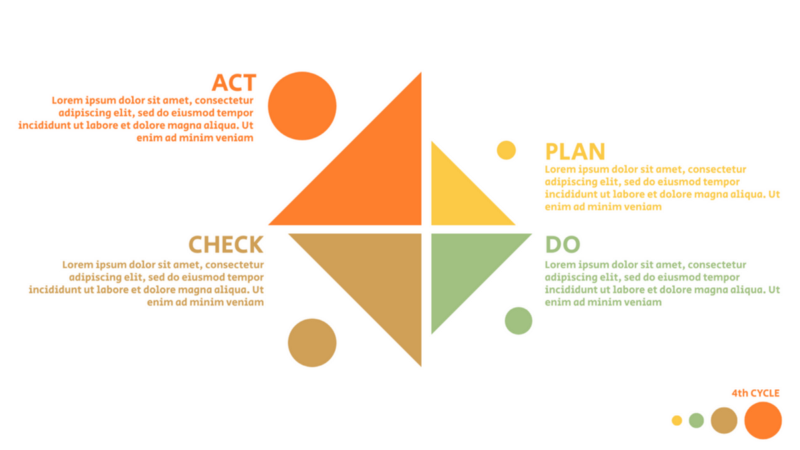

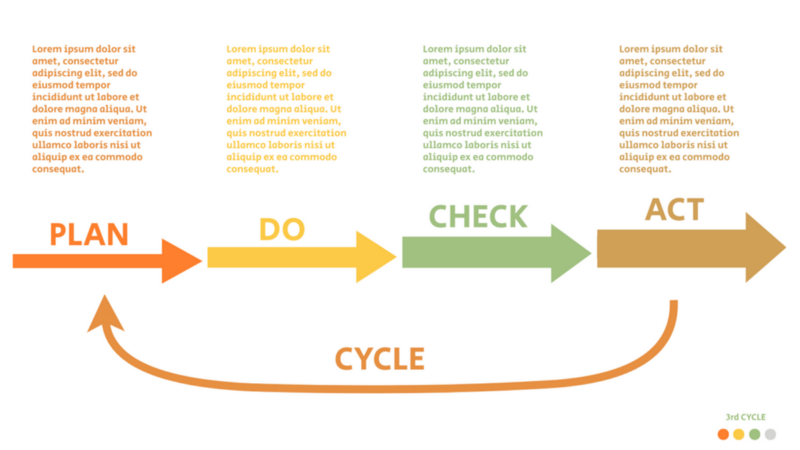

- Plan — The logical sequence starts with the plan and focuses on the strategic parts. The purpose here is to present and analyze information to set goals and objectives.

- DO — It’s time to implement by executing what was determined in the previous step

- Check: After the inspection, we will look to see if the operation has improved, for example, what is working and what is wrong? Are there any alternatives or solutions?

- Act: In this step, based on the finding of step 3, the PDCA concept suggests restarting the PDCA cycle in search of continuous and uninterrupted improvement.

Once completed the step 4, you have to return to the first step to implement more new improvements. If you look at the evolutionary control cycle, then you have to understand it as a never-ending process. There is neither a beginning nor an end. It is helpful to think of the Deming Circle as a spiral. A spiral that continues upwards. Every improvement takes your company to a new, better level.

The Meaning of PDCA Cycle

Every work can be treated as a PDCA cycle which:

- The needs to plan,

- Implement a plan,

- check the results, and

- Summarize and seek for further improvements.

Each effort is a four-part PDCA cycle that needs to be planned, implemented, reviewed, and further refined. At the same time, it will move into the next cycle. A qualitative leap, even a small one, can only be made over a period of gradual improvement. Only in this way can we improve our every work and life.

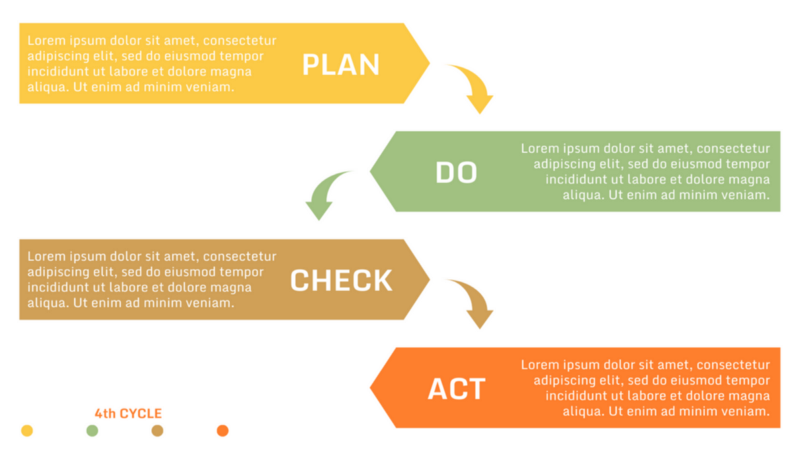

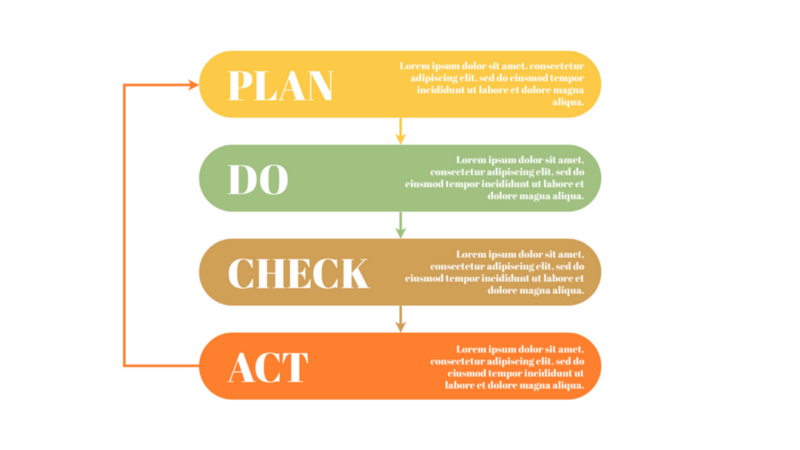

How to implement PDCA

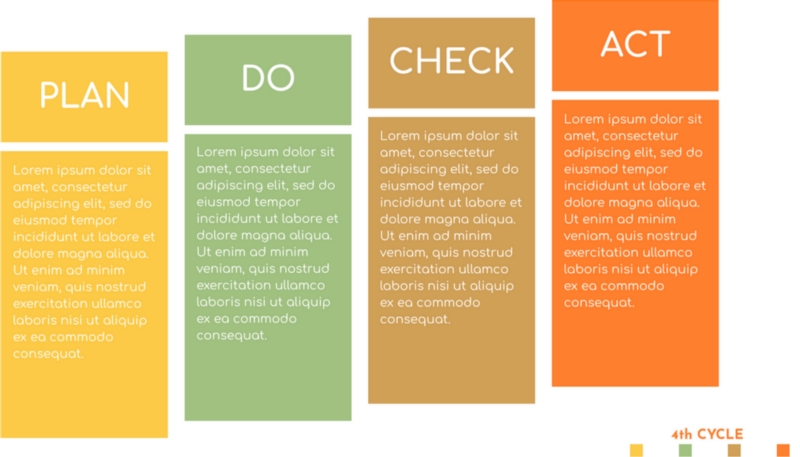

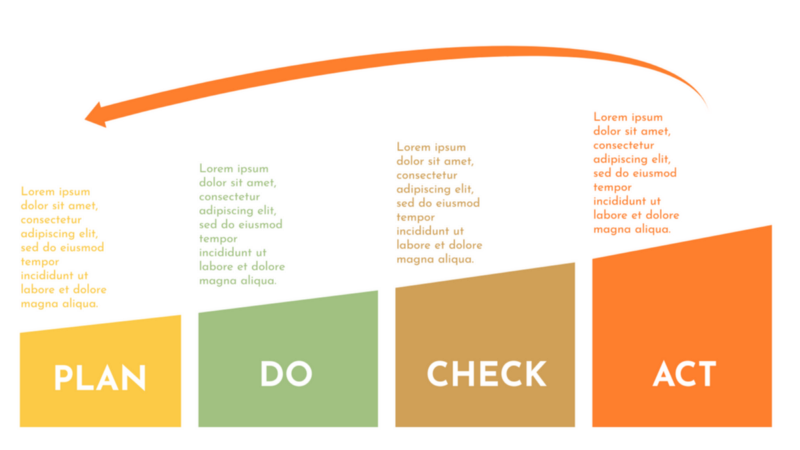

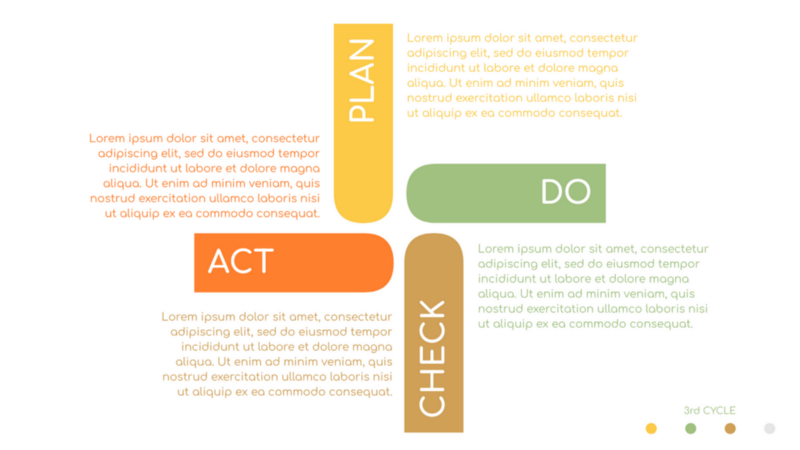

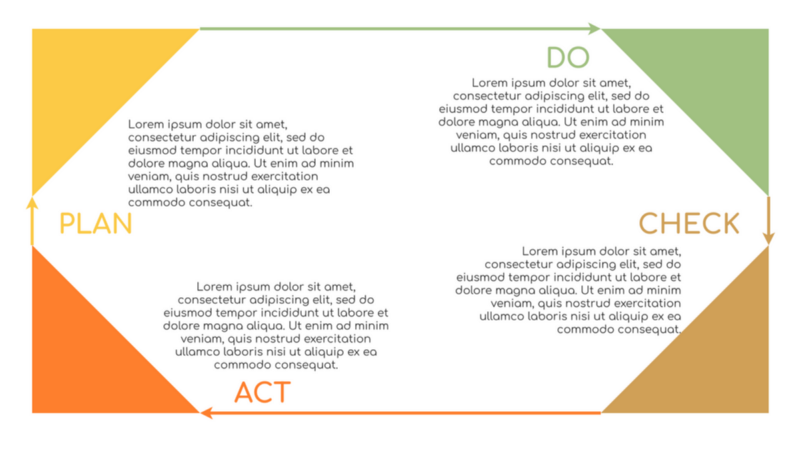

PLAN :

- Analyze the current situation and find out the existing problems;

- Analyze the cause or influencing factors of the problem;

- Find out the main cause of the problem or the main factor affecting;

- Develop measures and propose action plans;

DO :

- Implement an action plan;

CHECK :

- Evaluation results (analysis of data);

ACTION :

- Standardization and further promotion;

- Re-use the PDCA cycle in the next improvement opportunity;

It is important that you do not look at everything from an individual perspective, but as an entrepreneur always think in both small and large PDCA cycles and act accordingly. For you, the following motto must always be in the foreground.

Subdivide PDCA Cycle into 8 Steps

- Analyze the status quo to find out the existing quality problems: the warehouse is not standard, crowded, and messy.

- Analyze various causes or influencing factors that produce quality problems: 1. There are more materials and fewer shelves. 2. The area is not clear.

- Find out the main factors affecting quality: 1. Add shelves. 2. Re-division of areas.

- Aiming at the main factors of quality problems: 1. Develop measures and propose action plans. 2. Develop a division area.

- Implement action plan: 1. Add shelves, 1. organize materials. 2. Divide the area and sort the materials according to the area division.

- Evaluation result (analysis data): Check the area division and make a summary.

- Standardization and further retrospective review: communicate results with department staff and make records.

- Raise the unresolved problems in this cycle, and transfer them to the next PDCA cycle: if the plan cannot be completed, then carry over to the next improvement cycle.

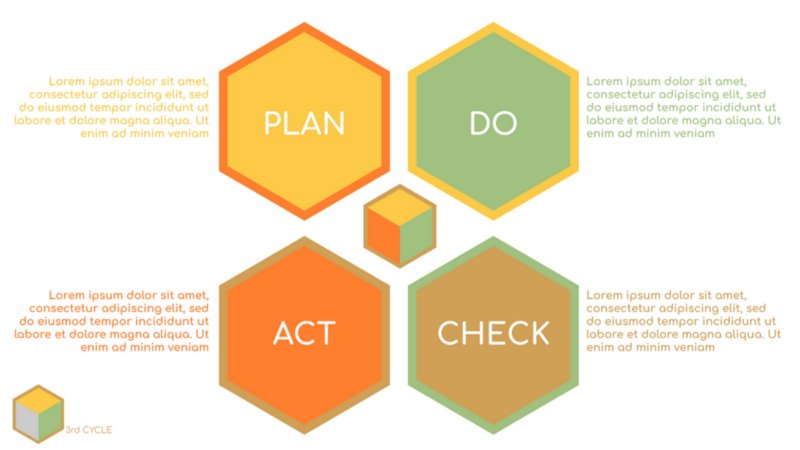

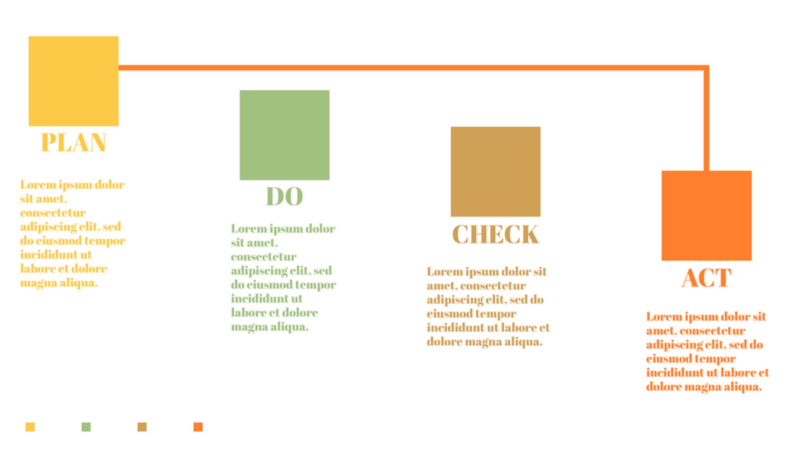

Hierarchical PDCA Cycle Structure for Large Organization

- The big ring has a small ring inside it. If the entire company works as one large PDCA cycle, then each of its departments, groups, and their own small PDCA cycles are embedded into it to form a PDCA hierarchy.

- Continuous Improvement of PDCA cycle — PDCA cycle is not at the same level of cycle, each cycle, to solve a part of the problem, achieve a part of the results, work on the further, the level of one step. In the next cycle, there are new goals and content, so that the ladder continues to rise.

Summary

PDCA cycle is the scientific procedure and integral part of total quality management, lean method, six sigma and other methods. For example, the whole process of total quality management activities is the formulation and organization process of quality plan. This process is carried out in accordance with the PDCA cycle, is continuous, repeated operation. The PDCA cycle is not only applied to the quality management system, but also applicable to all progressive management work.

The Best All-in-one Free Visual Design Tool

Even if you are not a professional designer, you can still easily create impactful infographics, flyers, posters, resumes, and brochures. Do it yourself, create like a pro, with InfoART’s all-in-one visual design solution. You can now create professional infographics, flyers and marketing visuals in minutes, with no design experience!

Get work done with minimal time and effort

Create professional content faster with better:

- Features: Layout component and drag-and-drop editor makes it fast to create and re-edit any design.

- In-tool resources: Save time in finding photos or cliparts because everything you need is already included in InfoART. Simply perform a search to get it.

- Templates: You don’t need to spend time on designing because a rich set of professionally designed templates are available.

This post is also available in Deutsch, Español, فارسی, Français, Bahasa Indonesia, 日本語, Polski, Portuguese, Ру́сский, Việt Nam, 简体中文 and 繁體中文.